Ultimate Guide to Plastic Sheet Butt Welding Machines (HDPE, PP & PVDF)

A deep engineering guide covering welding principles, material behavior, CNC control, and industrial applications.

Plastic sheet butt welding is the most reliable and widely adopted method for joining HDPE, PP and PVDF sheets in the fabrication of chemical tanks, ventilation systems, fume scrubbers, water treatment units and various industrial plastic assemblies.

Unlike introductory articles that simply define “what a plastic sheet butt welder is,” this guide goes deeper into:

• How HDPE, PP and PVDF behave differently during welding

• Why CNC control significantly enhances weld strength

• Why European engineering projects require DVS 2207 compliance

• What defines an industrial-grade plastic sheet butt welder

• Key engineering parameters that determine long-term durability

With 10+ years of experience exporting industrial welding equipment to Europe, Australia and Latin America, Weissenberg designs butt welding machines that meet international engineering requirements and CE safety standards.

1. Engineering Principles of Plastic Sheet Butt Welding

(Much more than “heating + pressing”)

High-quality butt welding depends on three fundamental engineering behaviors:

① Heat Transfer

The heating plate of a plastic sheet welding machine must maintain:

• Uniform temperature distribution

• ±5°C thermal accuracy

• Rapid temperature recovery

Any deviation may cause:

• Overheating → polymer chain degradation

• Underheating → insufficient molecular fusion

• Asymmetric or weak bead formation

② Molecular Fusion

Once HDPE, PP or PVDF reaches molten phase, polymer chains interlock and diffuse.

When controlled precisely:

👉 Weld strength can reach 90–100% of the base sheet material.

Fusion quality depends on:

• Alignment precision

• Stable, repeatable pressure

• Uniform molten layer thickness

③ Cooling Under Pressure

Cooling determines final weld strength:

• PP cools fast → prone to shrinkage

• PVDF is sensitive to pressure stability → risk of internal stress

Thus, industrial welding machines must control cooling pressure and cooling duration precisely.

2. Why CNC Control Matters in Modern Plastic Sheet Welding

CNC (Computer Numerical Control) ensures consistent, traceable, and repeatable welding quality—essential for industrial fabricators.

CNC enables:

✔ Automated heating and cooling cycles

✔ Consistent change-over timing

✔ Stable pressure control

✔ Deviational parameter alarms

✔ Complete welding record logs (traceability)

Learn more about our CNC-controlled butt welding process.

CNC transforms welding from manual craftsmanship into a standardized industrial process.

3. How HDPE, PP, and PVDF Behave Differently During Welding

Different polymers have completely different thermal and mechanical responses.

| Material | Melt Behavior | Sensitivity | Difficulty | Key Control |

| HDPE | High melt flow | Low | ★☆☆ | Bead width, temperature stability |

| PP | Rigid, cools fast | Medium | ★★☆ | Alignment, cooling speed |

| PVDF | Narrow melt window | High | ★★★ | Precision temperature control |

📌 Engineer’s Frequently Asked Questions:

“Why does PP warp while HDPE does not?”

Because PP cools significantly faster, causing internal stress and shrinkage if pressure is inconsistent.

4. DVS 2207 – Why European Projects Require It

Most European industrial fabricators require:

👉 “Plastic sheet fabrication equipment must comply with DVS 2207.”

DVS 2207 defines:

• Heating plate temperature window

• Change-over time

• Bead formation characteristics

• Alignment tolerance

• Cooling time requirements

• Surface preparation

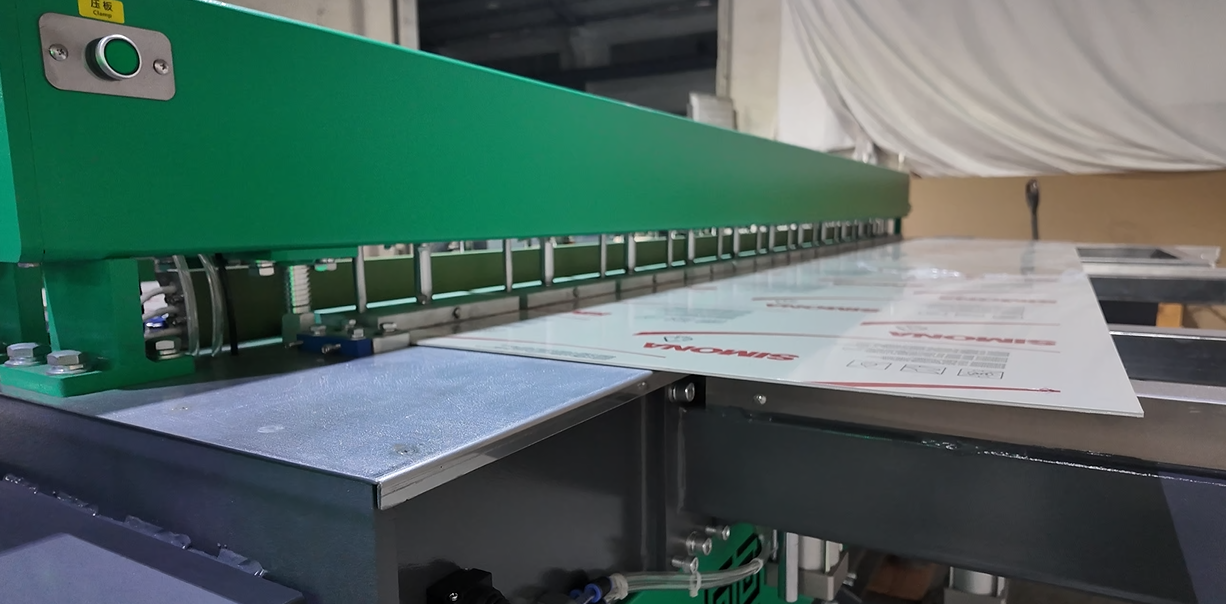

5. Standard Welding Workflow of a CNC Plastic Sheet Welding Machine

The typical CNC industrial sequence includes:

1. Sheet alignment and clamping

2. Heating plate contact

3. Heat soaking

4. Rapid change-over

5. Pressure fusion

6. Controlled pressure cooling

7. Bead inspection

You can review the full workflow in our CNC butt welding workflow.

6. Industrial Applications of Butt Welding Machines

Plastic sheet butt welders are widely used for:

• HDPE & PP chemical tanks

• Fume scrubbers & ventilation towers

• Water treatment modules

• HDPE fish farming tanks & aquaculture systems

• Electroplating tanks

• Industrial plastic sheet fabrication

See more industry examples in our aquaculture plastic sheet fabrication applications

7. How to Select a Professional-Grade Plastic Sheet Butt Welder

When evaluating a machine, engineers should consider:

✔ ±5°C temperature precision

✔ Scratch-resistant heating plate

✔ Stable pneumatic/hydraulic pressure (SMC recommended)

✔ High-accuracy alignment system

✔ Sheet thickness capability (e.g., 3–40 mm)

✔ CE + DVS compliance

✔ Rigid frame for industrial loading

8. Why Fabricators Worldwide Choose Weissenberg

Weissenberg butt welding machines are designed for industrial plastic sheet welding applications, offering:

• International brand components (SMC, Omron, Schneider)

• ±5°C temperature stability

• High-rigidity machine frame

• Accurate sheet alignment

• HDPE / PP / PVDF compatibility

• CE certification

• Exported to 30+ countries

Learn more about our plastic sheet butt welder models.

9. What This Means for Industrial Fabricators

Plastic sheet butt welding is highly sensitive to temperature, pressure, and cooling behavior—especially when working with engineering materials such as HDPE, PP, and PVDF.

For manufacturers of chemical tanks, ventilation systems, water treatment units, and other industrial plastic structures, a butt welding machine is not merely equipment; it directly determines the final component's:

• Mechanical strength

• Leak-tightness

• Chemical resistance

• Service life

Choosing a butt welding machine with stable temperature control, precise alignment, and industrial-grade pressure performance is essential to ensure that every weld meets strict mechanical, chemical, and dimensional requirements.

If you need welding parameters, equipment selection advice, or engineering recommendations for HDPE, PP, or PVDF fabrication projects, Weissenberg can provide technical guidance based on real industrial applications.