Zoned Temperature Control

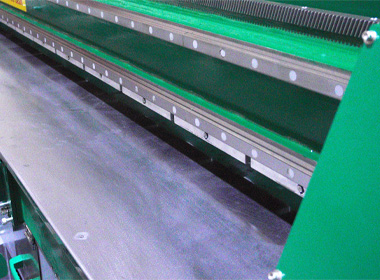

The heating plate maintains a temperature difference within ±5℃ across different areas, ensuring even heat distribution and preventing local overheating or underheating.

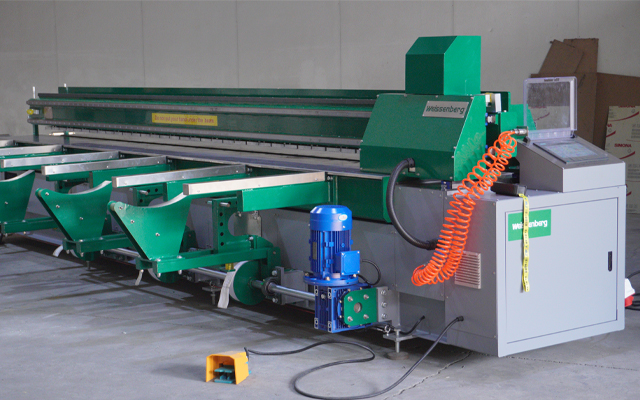

Our goal is to provide strong, leak-proof welds for PP spray towers to ensure safety and reduce rework. This improves efficiency, extends equipment life, lowers costs, and helps customers deliver reliable, high-quality products on time.

Get in Touch

The heating plate maintains a temperature difference within ±5℃ across different areas, ensuring even heat distribution and preventing local overheating or underheating.

The PLC system continuously monitors and adjusts welding parameters—temperature, pressure, and time—ensuring consistent and stable welding performance.

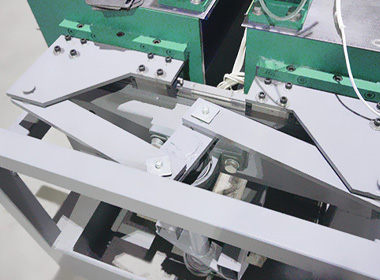

The parallelogram synchronization mechanism ensures the welding panels move uniformly, minimizing heat stress concentration and alignment errors.

Constructed with heat-treated steel and a high-precision flat platform, the machine ensures even heating and accurate alignment during welding.

If you have more matching needs, we can customize exclusive product matching solutions for you.

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.