Complete Guide to Plastic Sheet Fabrication Equipment — Made in China, Exported Worldwide

Introduction: From Sheet to Structure — The Weissenberg Approach

In modern thermoplastic fabrication, precision and reliability define every successful project.

At Weissenberg, we manufacture CE-certified plastic sheet fabrication equipment — including welding, bending, and 2-in-1 combination systems — designed and built in China, trusted by fabricators in Europe, Oceania, and Latin America.

Our goal is simple: help manufacturers transform thermoplastic sheets into durable, perfectly aligned structures — faster, safer, and more efficiently.

What Is Plastic Sheet Fabrication Equipment?

Plastic sheet fabrication covers the processes of welding, heating, and forming thermoplastic sheets such as HDPE, PP, PVDF, PVC, and ABS into usable structures like tanks, ducts, and housings.

Weissenberg provides three main categories of machines:

• Plastic Sheet Butt Welder – for strong, seamless sheet joints.

• Plastic Sheet Bending Machine – for precision and repeatable angles.

• 2-in-1 Welding & Bending Machine – for workshops that value compact, integrated production.

All models are designed following DVS 2207 standards and certified under CE regulations, ensuring consistent quality across international markets.

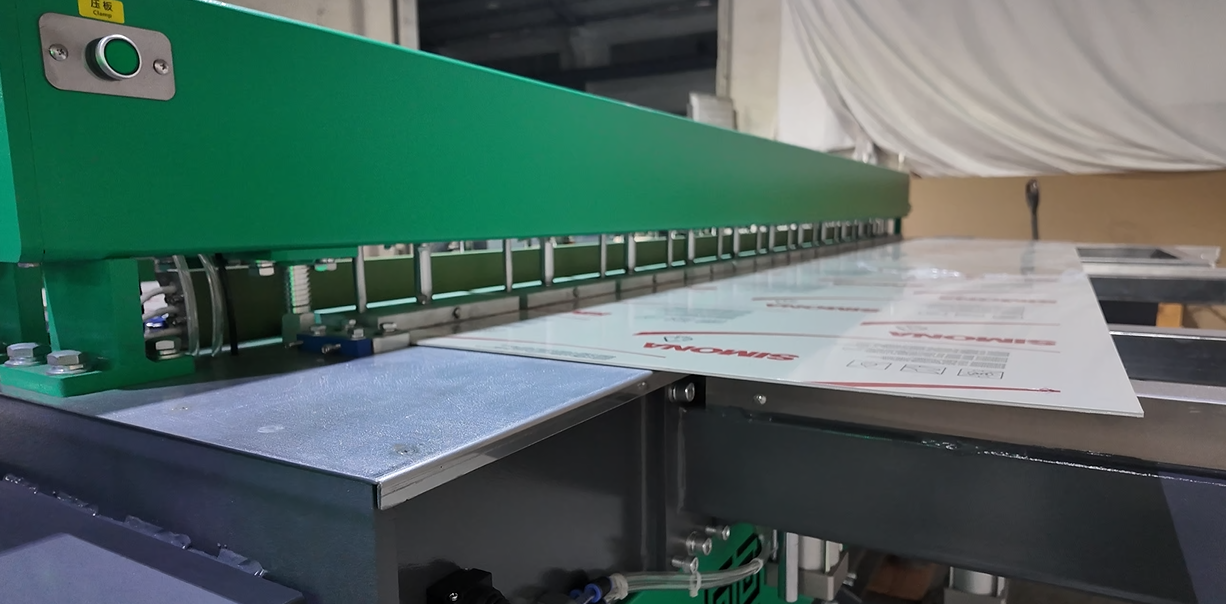

Plastic Sheet Butt Welders — Creating Unbreakable Joints

A plastic sheet butt welder uses controlled temperature and pressure to fuse two sheets into a single continuous panel.

The process delivers a molecular-level bond equal in strength to the base material.

Weissenberg’s WeiBond series (e.g., WeiBond 3000) offers:

•Precise heating control (± 5 °C plate accuracy);

•Uniform melting for consistent seam strength;

•Robust clamping and synchronized steel frame for steady pressure distribution;

•Durable heat-treated steel structure for long-term reliability;

•Compliance with DVS 2207 welding standards;

•Compatible with PE, PP, PVDF, PVC, ABS materials.

Typical applications:

•Chemical tanks and scrubbers

•HDPE ducts and panels

•Water treatment modules

•HDPE boat hull and pontoon structures

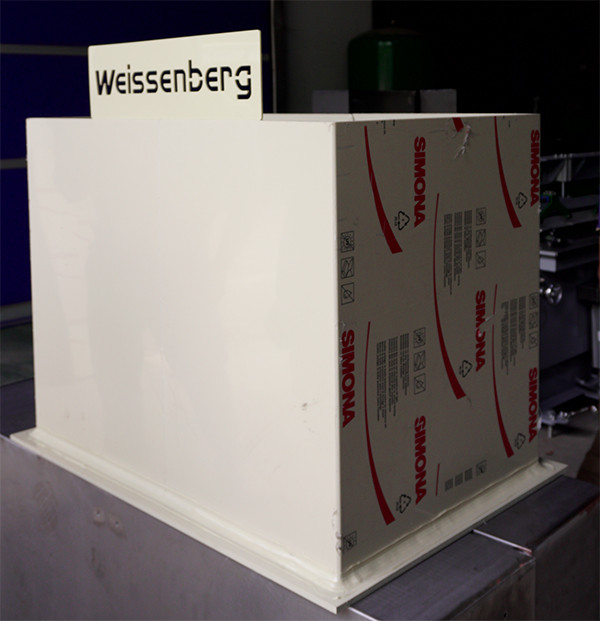

Plastic Sheet Bending Machines — Precision & Consistency

Weissenberg’s WeiFlex series (e.g., WeiFlex 5000) provides 5° – 95° adjustable bending angles and a maximum bending width of 5000 mm for PP, PE, PVC, PVDF sheets up to 25 mm thick.

Key advantages:

• Fast & stable heating for uniform melting along the bending line;

• Parallelogram structure ensures even pressure and precise angle alignment.

• Precision alignment scales for repeatable production quality.

• Remote error alert system for easy maintenance and safety.

• Built to CE and DVS 2207 standards.

Used in industries such as:

• Chemical equipment and storage tank fabrication

• Ventilation and exhaust ducting

• Water treatment and environmental engineering

• Fish farming and aquaculture tanks

2-in-1 Welding & Bending Machines — Efficiency in Action

For fabricators who value productivity and space efficiency, Weissenberg’s 2-in-1 plastic sheet welding and bending machines combine two operations in a single system.

Benefits:

• Reduces labor and handling time between welding and bending steps;

• Ensures consistent alignment of welds and bends;

• Compact design for limited workshop space;

• Digital control for repeatable settings and production efficiency.

• Ideal for HDPE and PP workshops requiring flexibility and high output.

Applications Across Industries

Weissenberg’s machines support a wide range of industries requiring precision plastic fabrication:

• Chemical processing — acid tanks and scrubbers.

• Environmental systems — water treatment and flue gas ducts.

• Aquaculture — PP/HDPE tanks and filters.

• HDPE boats and marine structures — decks and hulls.

Every system is built to deliver reliable performance and consistent results for heavy-duty industrial use.

Quality & Certifications That Matter

All Weissenberg machines are:

• CE-certified for safety and manufacturing quality;

• Compliant with DVS 2207 for welding accuracy;

• ISO-based production quality controlled at each assembly stage.

We combine international standards with local manufacturing efficiency to offer global customers trusted solutions.

Why Choose Weissenberg

• 19+ Years of Experience in plastic sheet welding and forming equipment.

• Global Trust — machines running in 30+ countries worldwide.

• Top-tier Components — Mitsubishi PLC, SMC cylinders, OMRON, SCHNEIDER electrics.

• Custom OEM Solutions tailored to client needs.

• Complete After-Sales Support — spare parts, training, and remote service.

We don’t just sell machines — we deliver precision, productivity, and peace of mind.

Get a Quotation or Technical Guide

Whether you are starting a new workshop or expanding existing capacity, Weissenberg provides reliable and cost-effective solutions for plastic sheet fabrication.

Contact Weissenberg today for CE-certified plastic sheet welding and bending machines — Made in China and trusted worldwide.