Standards-Compliant Welding

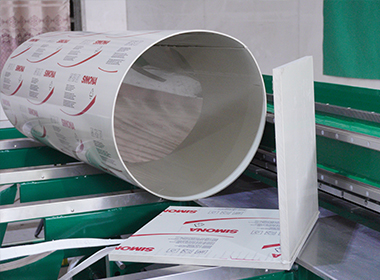

This welding machine meets DVS 2207 standards, ensuring consistent weld quality. It works with HD-PE, PP, PVC, PVDF, and other thermoplastics — ideal for diverse industrial needs.

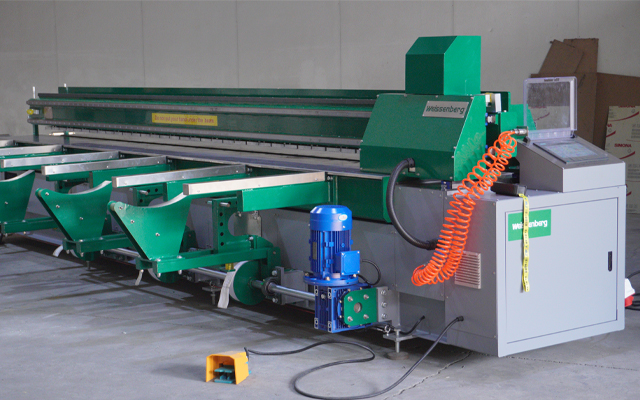

Weissenberg’s plastic sheet welders are built for HDPE and PP chemical tank fabrication, delivering strong, leak-proof welds with precise alignment. They reduce rework, boost efficiency, and ensure consistent quality — making tank production safer, faster, and more reliable.

Get in Touch

This welding machine meets DVS 2207 standards, ensuring consistent weld quality. It works with HD-PE, PP, PVC, PVDF, and other thermoplastics — ideal for diverse industrial needs.

The machine offers stepless height adjustment (up to 70mm) via a 4V motor, allowing precise control of the heating plate for even heat, better welds, and longer service life.

The high-density clamp applies even pressure to prevent defects and holds the workpiece steady to avoid movement or deformation. This ensures stable, consistent welds and reduces human error.

Mitsubishi PLC with touchscreen automatically adjusts pressure,

temperature, and time for accurate, strong welds- ideal for complex plating tank builds.

If you have more matching needs, we can customize exclusive product matching solutions for you.

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.