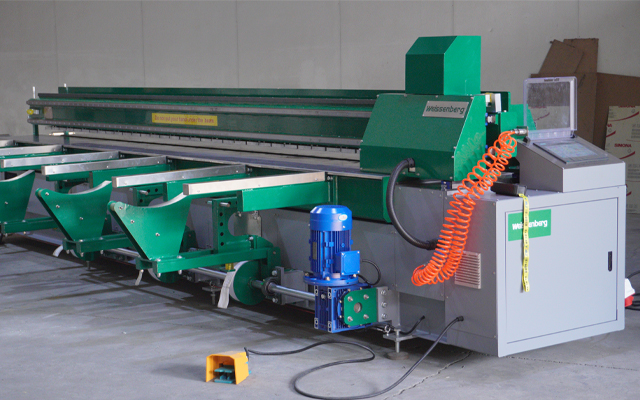

Even Pressure for Reliable Sealing

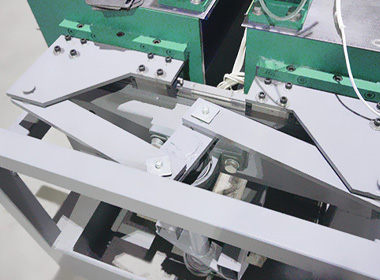

Using mechanical synchronous transmission and high-density locking clamps to ensure uniform pressure across the welding area, enhancing joint strength and eliminating common leakage risks in water treatment equipment.