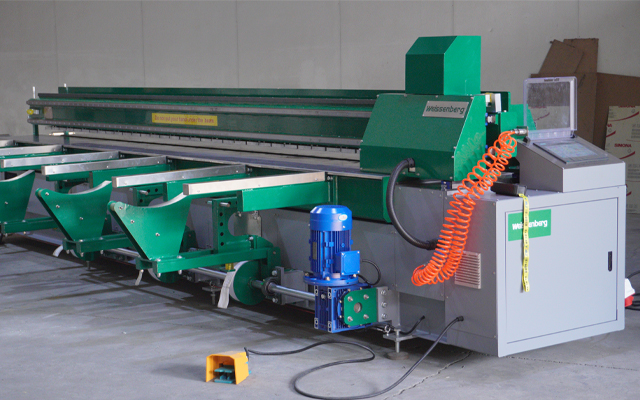

Stable Pressure Distribution

Strong steel frame and synchronous drive ensure even pressure via a regulating valve and high-density clamps, preventing leaks and poor sealing.

The goal is to ensure plating tanks are strong and well-sealed to prevent leaks and damage, ensuring safe production and environmental protection. At the same time, improving welding accuracy and efficiency helps extend service life, reduce maintenance costs, and meet customer demands — boosting satisfaction and competitiveness.

Get in Touch

Strong steel frame and synchronous drive ensure even pressure via a regulating valve and high-density clamps, preventing leaks and poor sealing.

Mitsubishi PLC with touchscreen automatically adjusts pressure, temperature, and time for accurate, strong welds- ideal for complex plating tank builds.

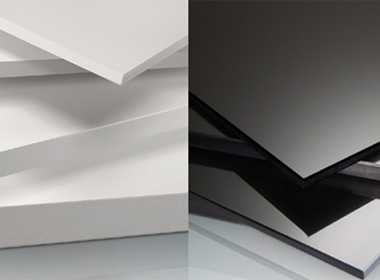

Handles various thermoplastics with welding thickness from 3mm to 30mm (up to 60mm for special needs), meeting diverse plating tank requirements.

Precise Temperature Control: Heating plate maintains ±5°C accuracy, ensuring uniform heat, reducing stress, and improving weld quality and corrosion resistance.

If our standard equipment does not meet your current project requirements, please leave us your specific needs and we will be happy to accept the challenge.

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.