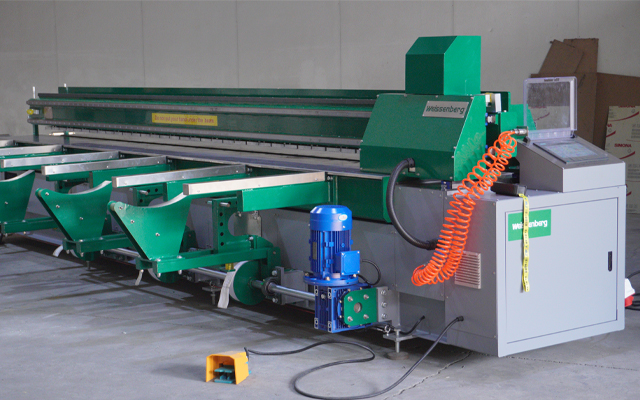

Tight Temperature Tolerance

Maintains a temperature variance within ±5 ℃ across all heating-plate zones to ensure even melting of plastic panels. This prevents weak spots in seams during long-term submerged use, thereby extending tank service life.

The purpose is to ensure weld sealing through uniform pressure and precise temperature control, improve efficiency and consistency with automated welding, reduce rework and costs via stable pneumatics and monitoring, and extend service life with a durable design to enhance the customer’s product competitiveness.

Get in Touch

Maintains a temperature variance within ±5 ℃ across all heating-plate zones to ensure even melting of plastic panels. This prevents weak spots in seams during long-term submerged use, thereby extending tank service life.

Mechanical synchronous transmission with high-density locking clamps provides uniform, stable pressure across the weld area, ensuring every seam carries equal pressure and preventing leaks from low-pressure spots.

Mitsubishi PLC and touchscreen let you pick programs for different materials and thicknesses, while heating plates auto-adjust to prevent warping or underheating, ensuring smooth panels and tight gasket seals.

Continuously monitors welding parameters (temperature, pressure, time), alerts on any anomalies, and logs data for each seam so operators can quickly fix issues and track history, greatly reducing rework.

If you have more matching needs, we can customize exclusive product matching solutions for you.

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.