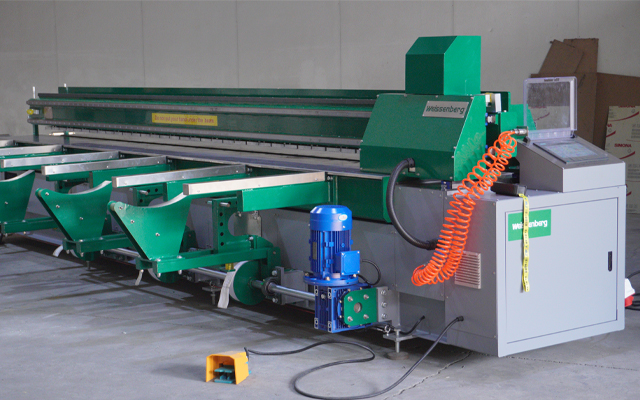

Weissenberg’s design and development team consists of over 15 experienced engineers. To date, our factory has successfully handled more than 400 non-standard equipment projects across a wide range of industries, including environmental protection equipment, electroplating systems, chemical container manufacturing, aquaculture, industrial exhaust gas treatment, and laboratory equipment.

With a high level of in-house manufacturing capacity, we are able to offer fast delivery—even for custom-designed welding equipment.

If your current project involves special welding requirements, feel free to leave it to us — we love a good challenge!

About Factory

Manufacture

Where Quality Begins

Weissenberg pioneered China's first plastic sheet welding and bending machines.

Our products are exported to over 50 countries, serving a wide range of clients in the plastic welding industry.

Completed 400+ custom projects in environmental protection equipment, electroplating, chemical containers, and industrial waste gas treatment.

With stable and reliable quality, we've had no major quality complaints in the past 19 years.

WEISSENBERG History

Strict Quality ManagementEnsuring Products Meet the Highest Standards

Still Using Old Welders?

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

Trusted in 30+ Countries

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Efficient Welding Solutions

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.

Get a Solution With Weissenberg Welder

- Name

- Phone

- *Title

- *Content