PID Temperature Controller

Integrate a PID-based temperature controller with dual feedback sensors to maintain set-point accuracy within ±2 °C

The solution objectives must focus on three pillars:

1. Achieving precise, rapid, and stable temperature regulation via advanced control algorithms and sensor integration;

2. Delivering fully friendly, diameter-based weld-depth selection using installed mechanism;

3. Enabling safe, ergonomic welding of suspended or elevated pipes through lightweight, modular clamping fixtures and portable support systems.

Integrate a PID-based temperature controller with dual feedback sensors to maintain set-point accuracy within ±2 °C

Preinstalled diameter-specific weld mechanism, eliminating manual estimation and ensuring proper penetration every time.

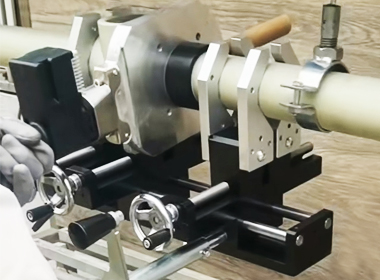

A lightweight, modular clamping fixture kit featuring adjustable arms and low-profile jaw assemblies that can attach directly to suspended pipes, maintaining concentric alignment without a bulky base unit.

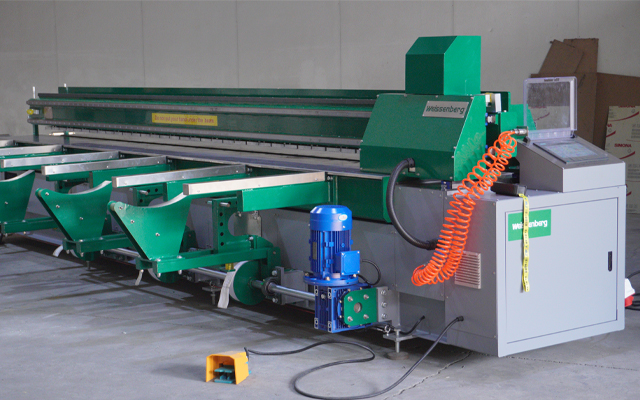

offering full-size and full-configuration options, covering the majority of mainstream market sizes and meeting both tabletop and overhead socket welding needs.

If you have more matching needs, we can customize exclusive product matching solutions for you.

Outdated tools slow you down. We offer reliable plastic sheet welding solutions with expert support to help you upgrade confidently.

From contractors to distributors, we deliver dependable welding machines and OEM/ODM support to improve your workflow and quality.

Whether OEM or ODM, our engineers provide tailored systems to optimize your process and deliver consistent, high-quality results.