Plastic Sheet Butt Welder | How to Weld 50 mm Hollow Panels

Page Summary (with key equipment parameter)

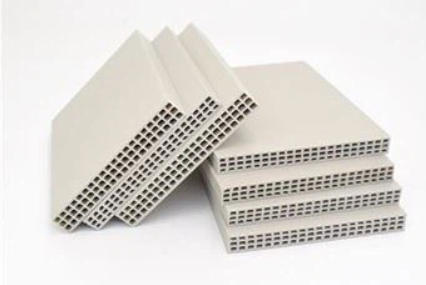

For PP/HDPE fabrications such as chemical tanks, electroplating baths, scrubber systems, construction panels, and aquaculture tanks, a Plastic Sheet Butt Welder is the preferred solution for butt welding 50 mm Hollow Panels (twin-wall, e.g., Paneltim). Our line supports an effective clamping opening of 63 mm, enabling stable clamping and pressing. Always finalize temperature/pressure/time via on-site welding parameters validation.

1. Why Butt Welding for Plastic Sheets (PP/HDPE twin-wall)?

Compared with mechanical fastening, butt welding/butt fusion (often called heat welding plastic sheet) delivers base-material-like strength, liquid-tight sealing, corrosion resistance, and repeatable quality—critical for PP/HDPE tanks, scrubber systems, and aquaculture tanks. This is why buyers looking for a plastic sheet welder or a welding polyethylene sheet solution choose plastic sheet butt welding for 50 mm Hollow Panels (Paneltim).

2. Solid vs. Hollow Panels: What Changes in Welding?

Solid sheets (3–30 mm) conduct heat faster and offer a wider window.

Hollow Panels (twin-wall, 50 mm) are light yet stiff; slower heat conduction and internal cells skew heat distribution.

Risks: uneven fusion, contamination, poor airtightness.

They are more sensitive to heating time, temperature stability, clamping, and alignment, so your plastic sheet welding machine must be configured for twin-wall panel welding.

3. SOP for Welding 50 mm Hollow Panels (Paneltim, PP/HDPE)

Validate on your line. Useful starting ranges: PP ~200–230 °C; PE ~190–210 °C. Narrow to your site-specific window after trials.

1) Preparation / Pre-treatment

Saw/plane edges; remove contamination/oxidation; keep edges square.

Check cell orientation; weld open side to open side.

Set clamping opening to 62–63 mm (tune for pad thickness) so parts load smoothly with sufficient stroke for pressing.

2) Clamping & Heating

Use a Plastic Sheet Butt Welder / PP sheet welding machine with an effective 63 mm opening; ensure parallel guides and accurate alignment.

Fit a wide heater bar (~80–85 mm) so skins and web transitions soften uniformly—essential for twin-wall butt welding.

Heat to the validation start; hollow panels usually need longer than solid sheets.

Keep the heater temperature stable and the edges softening synchronously.

3) Pressing & Cooling

Remove the heater and press immediately and smoothly, maintaining uniform pressure and alignment until the bead forms.

Keep clamped during cooling to prevent spring-back/mismatch; reinforce corners/holes afterward with extrusion welding or hot-air welding (same material).

4) Finishing & QC

Trim bead/flash; check seam symmetry and straightness (target mismatch ≤0.5–1.0 mm).

For liquid/pressure service, perform leak/pressure tests; do destructive sampling as required.

Document temperature, pressure, time, material batch, ambient, machine ID, and operator—build traceable records.

4. Weissenberg Case: Weibond 1500 (Solid vs. Hollow Use)

Solid sheets (standard) — 3–15 mm; fast heat conduction, uniform bead; stable mass production on standard settings.

Hollow panels (50 mm, engineered) — Raised fixtures provide a 63 mm effective opening; a ~85 mm wide heater covers skins and web transitions.

Result: uniform butt-welded seams on 50 mm Paneltim; strength and sealing meet engineering requirements after trials/inspection.

5. Equipment Selection for Hollow Panels (50 mm)

Clamping opening/stroke: 63 mm effective opening proven adequate for 50 mm Hollow Panels.

Wide Heating Plate: ~80–85 mm for uniform softening of skins and web transitions.

Alignment + force/position control: minimize mismatch and weak fusion.

Temperature + takt control: stable plate temperature and digital timing/alerts to replicate the window.

Data traceability: export/print parameters for QA audits.

Expandable tooling: 90° fixtures, corner reinforcement, edge-covering stations for extrusion/hot-air work.

6. Quality Control & Documentation

Visual/Geometric: symmetric bead, no charring/voids; straightness/flatness within tolerance.

Functional: leak/pressure tests for tanks and scrubber systems; witness tests if required.

Validation: define your window by small test welds for PP/HDPE and cell formats (50×50 / 50×100).

Records: temperature/pressure/time, material batch, ambient, machine ID, operator; include pad thickness, clamping opening 63 mm, pressing stroke/force, cooling time.

Pre-shift checklist — Opening 63 mm unloaded; re-measure after pads; heater insertion/removal without scraping; compare thin vs thicker pads; target mismatch ≤0.5–1.0 mm; bind parameters and test results to the work order.

7. FAQ

Q1: Which joint method is best for 50 mm Hollow Panels?

A: Mirror butt welding for the main seam; use extrusion/hot-air to cover corners, openings, or reinforcements.

Q2: Are there universal temperatures for PP/HDPE?

A: No. Start at PP 200–230 °C / PE 190–210 °C and refine by equipment, environment, and takt.

Q3: Is a 63 mm clamping opening enough for a Plastic Sheet Butt Welder?

A: Typically, yes for 50 mm twin-wall (Paneltim). If pads are thick or edges warped, optimize pad thickness and edge straightness, then confirm via trial setup/welds.

Weissenberg provides end-to-end solutions for plastic sheet welding:

Plastic Sheet Butt Welder systems (for PP/HDPE), plus extrusion and hot-air stations, and bending.

Engineering options include :

wide heater bars (~85 mm), 63 mm clamping openings (raised fixtures), alignment and force/position control, and data traceability. We support test-weld validation, training/installation, spares, and remote service.