2-in-1 Welding and Bending Systems: An Engineering Solution Under Real Constraints

In plastic sheet fabrication, welding machines and bending machines have traditionally been configured as standalone industrial systems.

From a purely engineering perspective, this separation remains the optimal solution in terms of single-process efficiency, continuous throughput, and long-term high-load operation.

This is why, in the European market, leading brands such as Ritmo and Wegener continue to treat welding and bending as independent processes, each optimized for maximum performance.

This paper does not challenge that engineering principle.

Instead, it addresses a different question—one that arises frequently in real-world workshops operating under practical constraints.

1. Defining the Engineering Context

In many small to medium-sized or growing fabrication workshops, production conditions are shaped by the following realities:

• Limited available floor space

• Restricted initial investment budgets

• Simultaneous need for welding and bending within the same project

• Intermittent or mixed production schedules

• Small-batch, multi-variant, or project-based manufacturing

Under these conditions, theoretically optimal configurations are not always practically achievable.

All conclusions in this paper are based on these assumptions.

Different conditions may lead to different equipment strategies.

2. When Ideal Configurations Are Not Feasible

In theory, the preferred setup would be:

• A high-spec plastic sheet butt welding machine

• A separate, high-precision plastic sheet-bending machine

However, many workshops face practical limitations:

• Insufficient space for two large standalone machines

• Budget constraints that prevent purchasing two industrial-grade systems

• Equipment utilization levels that do not justify such an investment

• Frequent process switching that introduces non-value-added handling

In these situations, insisting on standalone configurations at the cost of machine quality often leads to higher long-term risks rather than better outcomes.

3. The Real Motivation Behind 2-in-1 Systems

2-in-1 welding and bending systems were developed precisely in response to these constraints.

Their objective is clear:

Not to replace standalone machines,

but to enable industrial-level welding and bending

where space and budget limitations make separate systems impractical.

This represents a deliberate engineering trade-off, not a pursuit of peak performance.

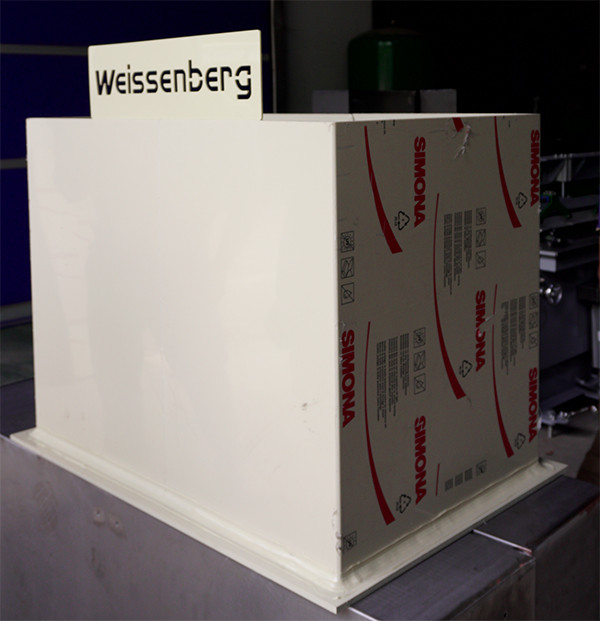

4. What Defines a True 2-in-1 Welding and Bending System

A genuine 2-in-1 system is not a simple functional combination.

From an engineering standpoint, it requires:

• A shared reference and alignment system

• Consistent clamping and positioning across processes

• Controlled integration that avoids process instability

• No compromise on core welding quality

As a result, such systems do not aim for maximum single-process throughput, but for reduced variability and simplified workflows.

5. Case Study: Engineering Decisions Under Real Constraints

A mid-sized workshop producing HDPE chemical tanks and industrial enclosures evaluated its expansion options.

The theoretically optimal configuration included:

• A high-spec plastic sheet butt welding machine

• A standalone plastic sheet-bending machine

However, limited space, restricted capital investment, and project-based production led the workshop to adopt a 2-in-1 welding and bending system, explicitly defining it as a phase-appropriate solution rather than a final production line configuration.

The decision was driven by feasibility, not by speed.

6. Why Space and Investment Matter in Practice

In many workshops, production capacity is constrained less by machine capability than by:

• Available space

• Available capital

• Available labor

Under these conditions, system-level balance often outweighs peak performance.

2-in-1 systems trade maximum throughput for lower entry barriers, compact layouts, and higher project feasibility.

7. Known Limitations: When 2-in-1 Systems Are Not Recommended

Standalone welding and bending machines remain the preferred solution when:

• Production is continuous and high-volume

• Welding and bending must operate in parallel

• Equipment utilization consistently exceeds 80–90%

• Space and capital are not limiting factors

Many mature manufacturers, therefore, adopt hybrid strategies, using standalone machines for main production lines and integrated systems for constrained or project-based work.

8. From Equipment Selection to Engineering Judgment

2-in-1 welding and bending systems are not inherently “more advanced,” nor are they intended to replace standalone machines.

Their value lies in this:

Under real-world constraints, they provide a viable engineering solution without compromising process integrity.

For a more systematic understanding of the structural logic, application boundaries, and engineering trade-offs involved in welding and bending systems, many manufacturers refer to the

Technical Guide to Plastic Sheet Welding and Bending Systems.