Troubleshooting Common Issues in Butt Fusion Welding

Optimize Fusion Quality with Weissenberg Butt Fusion Machines

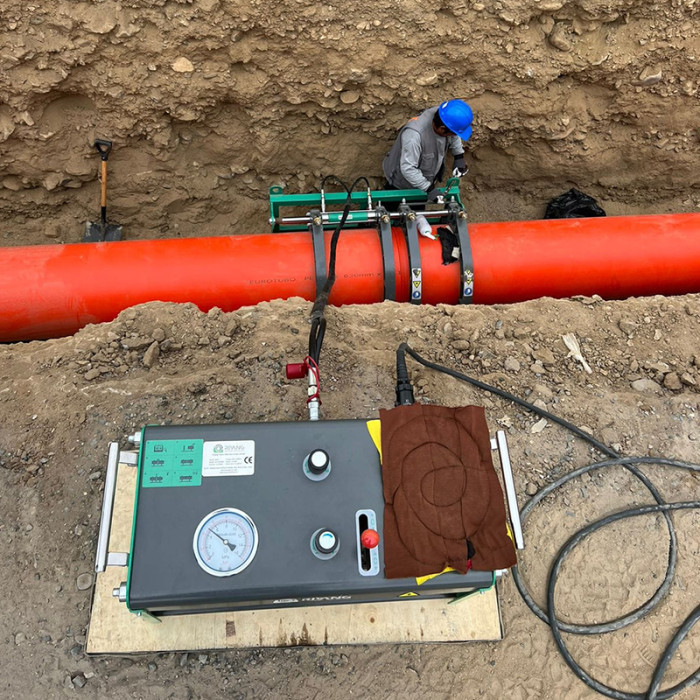

Butt fusion welding is a critical process for joining HDPE, PP, and PVDF pipes in industries such as water infrastructure, mining, and chemical processing. However, real-world operations often face challenges such as joint misalignment, internal voids, and inadequate bonding. In this guide, we explore the most common butt fusion issues and how Weissenberg high-performance equipment can help solve them—ideal for users searching for butt fusion machine, pipe fusion machine for sale, or hdpe butt fusion welding machine.

1. Joint Misalignment and Uneven Weld Beads

- Symptoms: Angled joints, inconsistent bead shape

- Causes: Pipe not clamped properly or poor machine alignment

- Solutions:

- Use equipment with an automatic centering system to prevent alignment errors.

- Weissenberg Riyang Series machines offer rigid clamping modules and guide rails to ensure precise centering—ideal for field and workshop use.

2. Air Pockets or Voids Inside the Weld

- Symptoms: Small cavities, inconsistent melt

- Causes: Moisture, oil, or improper heating

- Solutions:

- Ensure pipe ends are dry and contaminant-free before fusion.

- Weissenberg machines are equipped with ±2°C precise temperature control and real-time heating monitoring to deliver consistent fusion energy.

3. Weak or Overburnt Welds Due to Improper Heating

- Symptoms: Brittle welds, discoloration, or bubble marks

- Causes: Incorrect fusion temperature or time

- Solutions:

- We recommend automatic machines with Siemens PLC or digital control panels.

- Weissenberg Riyang Series automates heating, cooling, and pressure steps, reducing operator error significantly.

4. Misalignment from Pipe Shrinkage During Cooling

- Symptoms: Misaligned weld after cooling, edge separation

- Causes: Premature release or thermal contraction

- Solutions:

- Maintain pipe clamping until full cooling is complete.

- For large-diameter PE/PP pipes, anticipate shrinkage by adjusting preheat distribution accordingly.

5. Surface Contamination Not Properly Removed

- Symptoms: Weld peeling or insufficient bonding

- Causes: Poor edge trimming, dust or oxidation layer

- Solutions:

- Use professional edge-trimming tools for a clean, burr-free pipe end.

- Clean the heating zone with lint-free cloths and isopropyl alcohol before fusion.

Why Choose Weissenberg?

Weissenberg Riyang Series butt fusion machines are designed for industrial-grade, municipal, mining, and petrochemical applications. With smart control, durable structure, and global reliability, we are trusted by customers worldwide.

| Core Features | Description |

|---|---|

| ✅ Smart Control | Siemens PLC or digital panel with data logging & fault alerts |

| ✅ Modular Design | Manual, hydraulic, or CNC models for every project size |

| ✅ High Precision Fusion | ±2°C temperature accuracy; complies with DVS2207 / ISO21307 |

| ✅ Versatile Scenarios | Works in the field, plant, or trench |

| ✅ Global Certifications | Factory certified ISO 9001:2015, CE-compliant |

Frequently Asked Questions (FAQ)

Q1: What pipe materials are supported?

HDPE, PP, PVDF, and other thermoplastics.

Q2: Does Weissenberg support OEM/ODM?

Yes, we offer private labeling and structural customization services.

Q3: Can Weissenberg machines operate in extreme environments?

Our Riyang machines are designed for both high/low temperatures and rugged field conditions.

📍 Company: Weissenberg, Dongguan, China

🌐 Website: www.weissenbergwelder.com

📧 Email: inquiry@weissenbergwelder.com

Image prompt suggestion: “High-performance HDPE pipe butt fusion welding machine in use at a construction site, showcasing clamps.”