Plastic Sheet Butt Welder Buyer's Guide (2026) | How to Choose for HDPE, PP & PVDF

Introduction: From Process Understanding to Equipment Selection

In industrial plastic fabrication, understanding how butt welding works is only the first step. The real challenge begins when manufacturers need to select a machine that consistently delivers stable seams across different materials, thickness ranges, and production volumes.

As HDPE, PP, and PVDF flat sheets are increasingly used in chemical storage tanks, wastewater treatment systems, ventilation ducting, and corrosion-resistant assemblies, choosing the wrong butt welder often leads to rework, unstable joint quality, and hidden long-term costs. This buyer’s guide focuses on how to evaluate machines from a production and reliability perspective, rather than simply comparing specifications on paper.

What Is a Plastic Sheet Butt Welder?

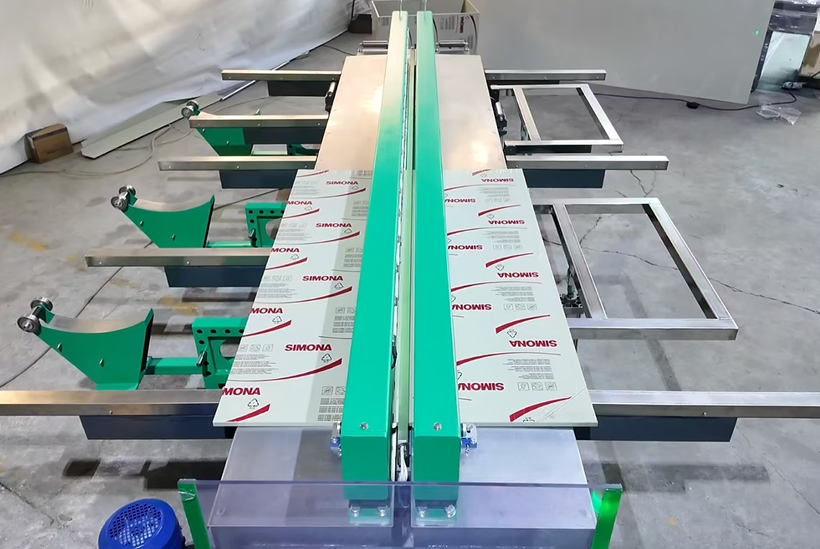

A plastic sheet butt welder (also known as a sheet fusion welding system) is an industrial heated-tool welding machine designed to join thermoplastic flat sheets such as HDPE, PP, PVC-U, PVC-C, and PVDF. During the process, both sheet edges are clamped, softened on a temperature-controlled heating plate, and fused under constant pressure to form a molecular-level joint suitable for structural fabrication.

In modern workshops, plastic sheet butt welding machines are widely used for producing large flat panels, modular tank sections, and long straight seams where joint strength and dimensional stability are critical.

Typical Applications in Europe & North America

Across European and North American markets, plastic sheet butt welding is commonly applied in:

• Chemical storage tanks and process vessels

• Wastewater and waste-gas treatment equipment

• Ventilation ducts and scrubber housings

• Structural flat panels for industrial enclosures

Driven by the rapid growth in HDPE/PP chemical tank fabrication, industrial plastic sheet welding equipment has become a standard solution for achieving repeatable, leak-resistant seams in large-format panel production.

Key Technical Factors That Actually Matter

1) Temperature Control Stability

Uniform heating across the entire heating plate surface is essential. Temperature fluctuation directly affects melt layer formation and seam integrity, leading to cold welds or overheating defects if not properly controlled.

2) Structural Rigidity and Alignment

Machine frame rigidity determines whether long sheets remain aligned throughout the fusion cycle. Structural deflection under load is a common but often overlooked cause of inconsistent seam geometry.

3) Pressure Control and Repeatability

Consistent fusion pressure ensures reliable molecular interdiffusion at the joint interface. Machines with stable pressure regulation deliver more repeatable seam quality across production batches.

4) CNC Automation and Process Recipes

For workshops handling repetitive production, CNC-controlled butt welders enable parameter storage, process repeatability, and reduced operator dependency. Automation improves throughput and minimizes variation between shifts.

5)Process Guidance and DVS Compatibility

While CE compliance addresses machinery safety, DVS 2207/2208 guidelines focus on welding process quality. Equipment that supports stable process control simplifies quality management in regulated fabrication environments.

Butt Welding vs. Extrusion Welding: Selecting the Right Method

| Fabrication Task | Butt Welding | Extrusion Welding |

| Large flat panels | ✅ Ideal | ❌ Not suitable |

| Long straight seams | ✅ High joint strength | ⚠️ Limited |

Structural joints | ✅ Recommended | ⚠️ Reinforcement only |

| Corners and fillets | ❌ Not applicable | ✅ Suitable |

In practice, butt welding is typically used for panel fabrication, while extrusion welding is applied for corner joints and localized reinforcement. Selecting the correct method prevents misapplication of equipment and improves overall fabrication efficiency.

Common Buyer Mistakes and How to Avoid Them

Many procurement challenges arise not from machine defects, but from mismatches between equipment capability and real production requirements:

• Focusing solely on purchase price instead of production stability

• Ignoring structural rigidity for long-panel applications

• Underestimating operator dependency in manual systems

• Choosing machines with insufficient welding length or thickness capacity

In real-world production, small process adjustments often improve seam repeatability more effectively than hardware changes—but only when the machine platform itself is stable and properly matched to the application.

A Practical Buyer Checklist

Before finalizing your purchase, clarify these points with your supplier:

1. Supported materials and thickness ranges

2. Maximum effective welding length

3. Heating plate temperature stability under continuous operation

4. Pressure control mechanism and repeatability

5. CNC automation options for recipe management

6. Pre-shipment testing and documentation

7. Technical support and spare parts availability

From Selection to Stable Production

Selecting a plastic sheet butt welder is not simply about choosing a model—it is about building a stable production system. When heating is uniform, structural rigidity is sufficient, and fusion pressure is consistent, seam quality becomes predictable rather than a production risk.

This is what separates occasional successful welds from repeatable industrial fabrication.

Next Steps: Talk to Engineers Before You Decide

Looking for the right plastic sheet welding solution for your application?

Tell us your sheet material, thickness, and project requirements — our engineers will recommend a suitable configuration for your process.