6m Plastic Sheet Butt Welder: Selection & Specs (Long-Bed/90° Vertical)

Introduction | Solving Large-Format Sheet Welding

When fabricating large HDPE/PP panels and tank shells, common pain points include too many seams, difficult alignment, unstable heat/pressure control, and inconsistent appearance. A 6-meter long-bed plastic sheet butt welder (plastic sheet welding machine) welds longer sheets in a single cycle, cutting seam count and alignment steps while improving yield and visual consistency—ideal for visible panels and cylindrical parts.

Why Choose a 6-Meter Model

1)Efficiency: One-Pass Long Seams

• With a 6 m sheet butt welding machine, each cycle completes extra-long joints → fewer seams, and less rework.

• 3 m segmented clamping and saved recipes shorten changeovers—ideal for repeat jobs.

2)Precision: Controlled Temperature/Pressure/Speed

• Closed-loop temperature, pressure, and travel-speed control stabilizes quality and aligns with DVS 2207 process principles.

• 0.01 mm servo-controlled lift helps keep long-seam bead appearance consistent.

3)Versatility: Flat, Vertical 90°, and Rolling

• Flat panel work with a plastic panel butt welder for large sheets.

• 90° vertical welding for box corners and L-panels (23 suction cups).

• Rolling/cylindrical welding (roll support) for tanks, ducts, and sleeves.

Industries & Typical Applications

• Chemical & Process: PP/HDPE tanks, scrubbers, pickling systems, fume-extraction components.

• Building & Waterproofing: façade/backer panels, protective sheets, prefabricated geomembrane panels.

• Signage & Display: long light boxes, advertising boards, shop-fit panels with uniform appearance.

• Environmental Engineering: filtration housings, water-treatment panels, HDPE/PP ducting and fittings.

Technical Features — 6 m Sheet Butt Welding Machine

• 6 m long-bed plastic sheet welding machine with 3 m segmented clamping; fewer seams, higher throughput.

• 90° vertical welding (23 individually controlled pneumatic suction cups) + rolling/cylindrical welding for HDPE/PP tanks and large panels.

• Heating-plate temperature accuracy ±5°C; 0.01 mm servo lift; 70 mm lift travel—stable, repeatable beads.

• Synchronized steel worktable + high-density locking clamps → even pressure, precise positioning, consistent appearance.

• Mitsubishi PLC sequences & parameter management; parameters saved for traceability; process aligned with DVS 2207.

• Key components from Mitsubishi / SMC / Omron / Schneider for long-term reliability and maintainability.

Long-Bed (6 m) vs 3 m — Sheet Butt Welder Comparison

• Seam count: moving from 3 m to 6 m halves seams per side, cutting alignment, and cosmetic finishing.

• Cycle time: one long pass replaces multiple setups; less idle; more predictable shift output.

• Consistency: fewer splices reduce tolerance stack-up → better flatness and visual uniformity.

• When 3 m fits better: short/custom parts, frequent mix changes, limited floor space.

• Conclusion: if ≥50% of parts exceed 3 m on one edge or need higher appearance/sealing consistency, a 6 m long-bed thermoplastic sheet welding machine is usually more economical.

Selection Checklist

1. Materials & thickness window: match heater power and clamping to HDPE/PE & PP min/max thickness.

2. Part mix: if many parts are <3 m, plan how often the 3 m segment mode boosts takt time.

3. Corners & cylinders: frequent box work → prioritize 90° vertical; cylindrical/duct work → confirm roll kit & minimum diameter.

4. Process control: recipes, temp/pressure/speed logging, and event logs (DVS-aligned).

5. Fixturing & handling: validate 23-cup layout, assist rollers, hard stops, and max sheet size.

6. Line integration: footprint, power/air, safety clearances, ergonomic flow.

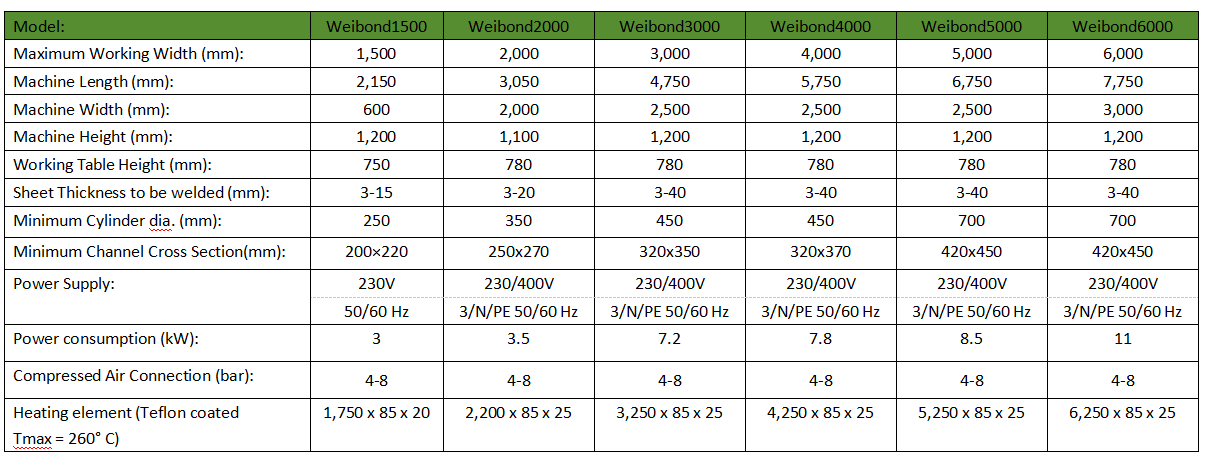

Specs Table

Customer Case (Results in Practice)

Background: a tank line previously stitched side panels with multiple 3 m seams.

Action: switched to a 6 m long-bed plastic sheet welding machine, reducing one side from two seams to one.

Result: fewer alignment/finishing steps; improved seam appearance; standardized parameters via recipes across shifts; suction-cup assist lowered handling effort. Most lines see higher first-pass yield and less rework (ROI varies by thickness and batch size).

FAQs

Q1: What thickness range can a thermoplastic sheet welding machine (6 m) handle?

A: Configurable—heater power and clamping are matched to your HDPE/PP thickness window.

Q2: Can large 90° corners be welded reliably on a plastic panel butt welder?

A: Yes—the 23-cup pneumatic system stabilizes sheets in vertical mode, improving angle accuracy and seam consistency.

Q3: What is the minimum rolling diameter with the rolling/cylindrical sheet welder?

A: Depends on thickness/material/fixtures; we’ll recommend a roll kit and achievable diameters for your typical tank sizes.

Q4: How do you ensure consistent weld quality on a DVS 2207 thermoplastic sheet welding machine?

A: Closed-loop temp/pressure/speed, 0.01 mm servo lift, matched contact surfaces, DVS-guided recipes/records—plus synchronized table and high-density clamps for full-length consistency.

About Weissenberg

Weissenberg specializes in thermoplastic sheet welding machines (butt welding, bending, and related equipment) for industrial HDPE/PP applications. Guided by DVS 2207, we deliver engineered configurations, commissioning, and training for chemical, environmental, building, and display sectors with verifiable quality and throughput.

Call to Action

Ready to upgrade to a 6 m long-bed sheet butt welding machine? Share your materials, thickness range, maximum part size, and output targets. We'll recommend the right configuration (vertical kit, rolling support, heater power, clamping force) and provide a matched cycle-time estimate and quotation.

Contact Weissenberg (inquiry@weissenbergwelder.com) to get your spec and quote.