3mm PP Sheet Welding Problems: Causes, Fixes & Best PP Sheet Welding Machines | Weissenberg

Why Does Welding 3mm PP Sheet Warp? Causes and Fixes Explained

Short answer: Thin polypropylene (PP) sheets shrink as they cool. When welding heat is too high or cooling is uneven, internal stresses cause warping. The best solution is precise heat control, correct sequencing, firm clamping, and using a reliable PP sheet welding machine or other advanced polypropylene welding equipment designed to minimize distortion.

Who Is This Guide For?

This guide is written for fabricators, plastic tank builders, and workshop professionals who regularly weld 3 mm PP sheets for trays, lids, covers, and chemical components. It also helps engineers compare hot-air versus extrusion welding methods, or those looking for the best plastic sheet welder for thin polypropylene applications.

About Weissenberg:

Weissenberg is a global leader in thermoplastic welding technology. We manufacture high-performance PP sheet welding machines, extrusion welders for PP, and other specialized polypropylene welding equipment that ensure consistent temperature, pressure, and quality across industries.

Why Does 3mm PP Sheet Warp During Welding?

1. Heat Input and Shrinkage

Polypropylene is highly sensitive to heat. Overheating creates localized melt zones that shrink unevenly during cooling. Thin sheets, such as 3 mm, are especially prone to distortion because they have less thermal mass.

2. Uneven Cooling Between Welds

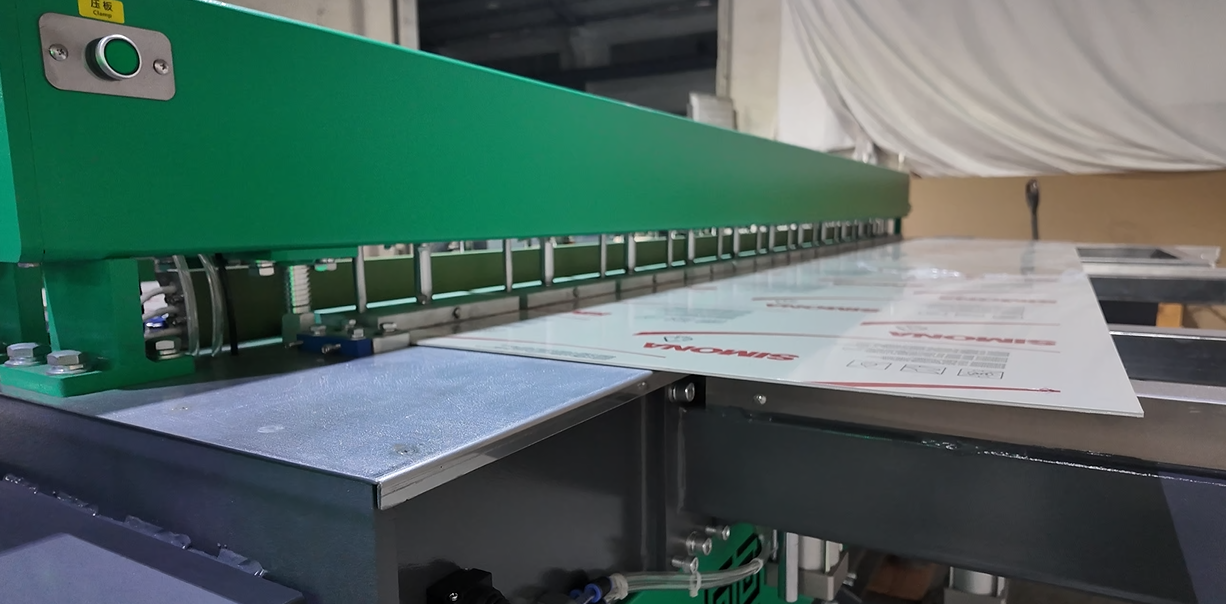

If weld seams are made in quick succession, stress accumulates before the sheet has cooled. The SIMONA welding guide recommends allowing each seam to air-cool fully and alternating weld sides so that stresses are balanced.

3. Incorrect Temperature Window

According to welding experts such as S-Polytec, PP hot-air welding should be carried out at around 230–280 °C. Going above this range risks surface burning, weak beads, and increased distortion.

How to Prevent Warping in 3mm PP Welding

• Control temperature: Keep tools within 230–280 °C. A PLC-controlled PP sheet welding machine ensures heat stability.

• Alternate welds: Use symmetric sequences, welding opposite sides in turn.

• Clamp and support: Fix the sheet on a flat, rigid table with high-strength clamps.

• Allow cooling: Air-cool each seam naturally before moving on.

• Match filler rod: Always use a matching PP welding rod for consistent shrinkage behavior.

Choosing the Right PP Sheet Welding Machine

A reliable plastic sheet welder is essential for distortion-free results. Look for:

• Stable temperature and airflow with PLC/PID control.

• Even pressure application for butt welds.

• Parameter storage and traceability for repeatability.

• Compatibility with an extrusion welder for PP for thicker sheets.

• Compliance with DVS 2207 international welding standards.

• High-Performance PP Sheet Welding Machines with Mitsubishi PLC control for precision.

• Extrusion welders for PP covering sheet thicknesses from 3 mm up to 40 mm.

• Full lines of polypropylene welding equipment are trusted in the chemical, marine, and water-treatment industries.

Practical Use Cases

• Large panels or lids: Use ribs or external supports to resist thermal pull.

• Precision trays and tanks: Shorten bead length and stagger welds.

• Corners and edges: Preheat gently and reduce dwell time to avoid corner lifting.

FAQ

Q1: What temperature should I use for PP welding?

The practical range is 230–280 °C, depending on sheet grade and welding speed. A modern PP sheet welding machine maintains this range accurately.

Q2: Why does a 3mm PP warp more than a thicker sheet?

Because thin sheets heat and cool faster, they shrink more unevenly, making distortion more noticeable.

Q3: Can a better machine reduce warping?

Yes. High-quality plastic sheet welders and extrusion welders for PP provide stable heat and pressure, which greatly reduces warpage.

Conclusion

Welding thin 3 mm PP sheets is challenging due to shrinkage and stress buildup, but with the right techniques and tools, warping can be prevented. By controlling heat, sequencing welds properly, and choosing advanced PP sheet welding machines or other polypropylene welding equipment, fabricators can achieve flat, durable, and professional-quality welds.

👉 Learn more about Weissenberg: About Us

👉 Explore our solutions: Weissenberg PP Sheet Welding Machines